Rectangular Magnets for Steel Lifting

|

Rectangular magnets are useful for the transport of slabs, ingots, billets, plates, pipes, steel bars, beam profiles and structural steel. These magnets can be adapted in line to structural conditions to meet the customer's existing configuration and requirements. The Magnet beam can be equipped with a mechanical safety device to avoid loss of material during power failure. |

Horizontal Coil Tong Harbour

|

The horizontal coil tong is designed to handle coils in the horizontal position for ship loading.

The gripping pads or shoes can be easily removed for maintenance, repair or replacement. |

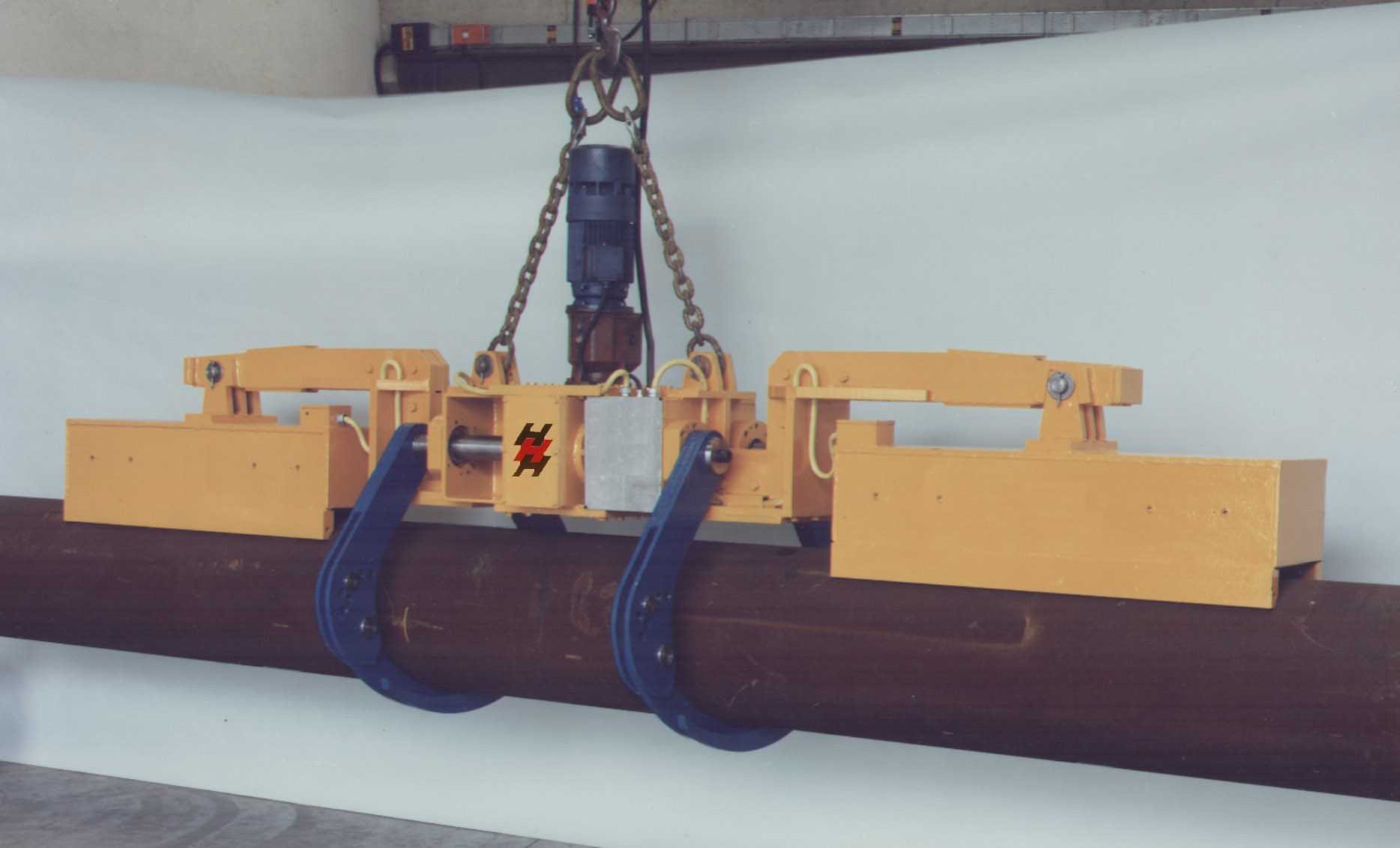

Hydraulic Operated Slab Tong

|

The Hydraulic Operated Slab Tong from Heppenstall Technology is able to lift either one or several slabs simultaneously. The lifting arms are pre-positioned before the lowering the tong onto the slab until the base of the tong contacts the surface of the slab. At this point the hydraulic system for closing the lever is actuated again. |

Motorized Sheet Lifter

|

The Motorized Sheet Lifter from Heppenstall Technology is designed to handle sheet packs in flat position. To lift sheet packs the lifting legs are moved out sufficiently to clear the pack to be lifted. Then the sheet lifter is lowered over the sheet pack until the lifting angles can grip under the pack. The lifting arms can be closed until they move against the sides of the sheet. To unload the lifter the operator must simply reverse the process. |